We serve you:

Efficiently

Reliably

Consistently

We understand the needs of original equipment manufacturers across many industries.

Midstate Spring’s Ideal Customer Profile:

1

Values safe and reliable products2

Minimizes supply chain risk and total costs3

Values efficiency and time saved4

Evolves with a changing market

Consumer Products

Running the gamut from recessed and wall wash lighting to stylish kitchen trashcans and cast iron cookware, our wire forms and springs ensure your products perform to your customers’ expectations. Hitting a seasonal or holiday spike? No problem! We can quickly scale to meet your demand.

Need millions of consistent pieces per year at a competitive cost? Let’s partner together on a stocking agreement to design, build and manage an automated multi-machine cell to satisfy your demand.

Energy

From the large wire springs found in transformer pressure relief devices and wind turbine gear mechanisms to the micro-wire springs used in electrical connectors, our springs deliver the reliability you need to power the world. Our custom large wire springs can support your onshore and offshore drilling and power management projects.

Fasteners

Springs, screws, nuts, bolts, and wire forms — this is the hardware that holds things in place and supports planned movement. Our quality springs and wire forms, coupled with our consistent on-time delivery, will help make your next contract manufacturing project a success.

Does one of your customers need a part in a hurry? Nearly a third of the orders we receive request shipment sooner than our standard lead time — and we make it happen.

Firearms

Supporting over two dozen firearms companies has taught us that you are passionate about your product! We are ITAR registered, and our engineers work closely with your R&D teams as they rapidly develop the next generation pistol, shotgun, or rifle. We manufacture prototypes within 1 to 2 weeks on our production equipment so you can get to market—fast!

Magazine springs, buffer springs, hammer and trigger springs, scope springs, the list goes on and on… new customers keep seeking us out for the exceptional quality of our custom firearm springs and our engineering support.

Heavy Truck

Throughout the world, you can find our springs in the mirrors and overhead roll-up doors of tractor-trailers. These heavy-duty springs are manufactured to withstand the harsh weather conditions and mechanical stress of thousands of hours on the road.

Our long-term partnerships with reliable finish suppliers ensures the plating on your parts will live up to the proven salt-spray test results.

Industrial

Does your business build heavy equipment? From construction equipment to road maintenance and farm equipment, we know your products. Our custom large wire springs will withstand the forces of your high-impact applications.

Our expertise includes in-house grinding, set removal, shot peening, passivation, and color code, leading to a consistent product for highly stressed springs.

Lawn and Power Products

Our quality deck and seat springs will enhance the comfort and stability of your Zero Turn mower. Need engineering spring design expertise for your prototype Stand On mower? Look no further. Team Midstate is here to help.

We know you ramp up early in the year for the mowing season. We have long term partnerships with reliable plating suppliers so that you get the parts you need, when you need them, and can meet your build targets.

Medical

The last time you visited a doctor, there’s a good chance the doctor used a pen light (with our wire forms inside as battery contacts) during the exam. Our springs and wire forms are also found in scopes and subcutaneous infusion systems.

We understand the controlled manufacturing environment required by your industry. We manufacture with wire diameters as small as .002 inches. Our premier Micro-Wire staff has over 25 years of experience mastering the intricacies of microscopic wire, so we’re ready to support your next project.

Power Tools

Whether your customer is a homeowner working on a weekend project or a seasoned construction professional, our springs reliably deliver the force your tools need to get the job done.

We are experienced with high volume cells that include grinding, set removal, in-house shot peening, passivation, and color code. This allows us to be cost competitive, while providing a consistent product for highly stressed springs within small design pockets.

Solenoids

High performance solenoids are your business and our business is to provide you with high precision springs.

We have many years of experience working closely with R&D departments in your industry. We deliver high quality, tight tolerance, ground, in-house shot peened springs that are manufactured under a capable, repeatable process where the springs are right the first time, every time.

Transit

Passenger safety is at the forefront of our minds when we manufacture the tight tolerance springs required for locomotive air brake valves. Whether it’s passenger transit or freight rail, your employees and customers are worth the consistent quality and precision craftsmanship of a Midstate spring.

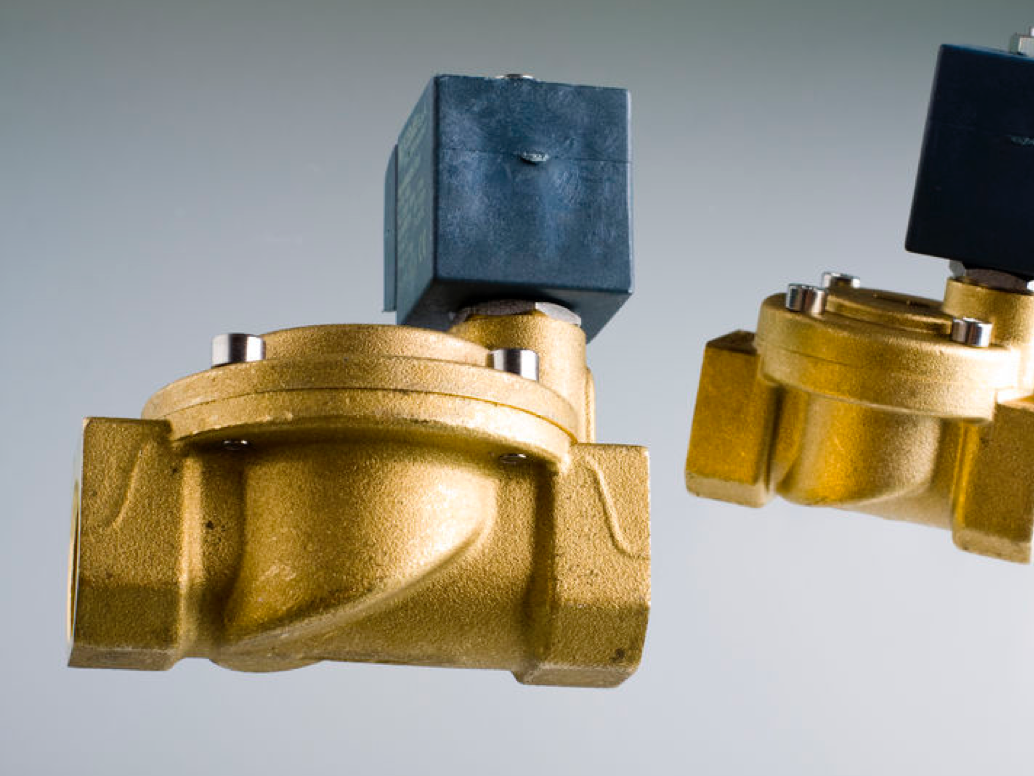

Valves

Working closely with engineers in your industry, we help them find solutions to their flow control challenges. Our precision quality valve springs will consistently deliver the required tension throughout the life of your product.

We produce tens of millions of valve springs every year and are experienced with high volume cells that include grinding, set removal, in-house shot peening, passivation, and color code. This allows us to be cost competitive, while providing a consistent product for your tight tolerance applications.